Project under

development

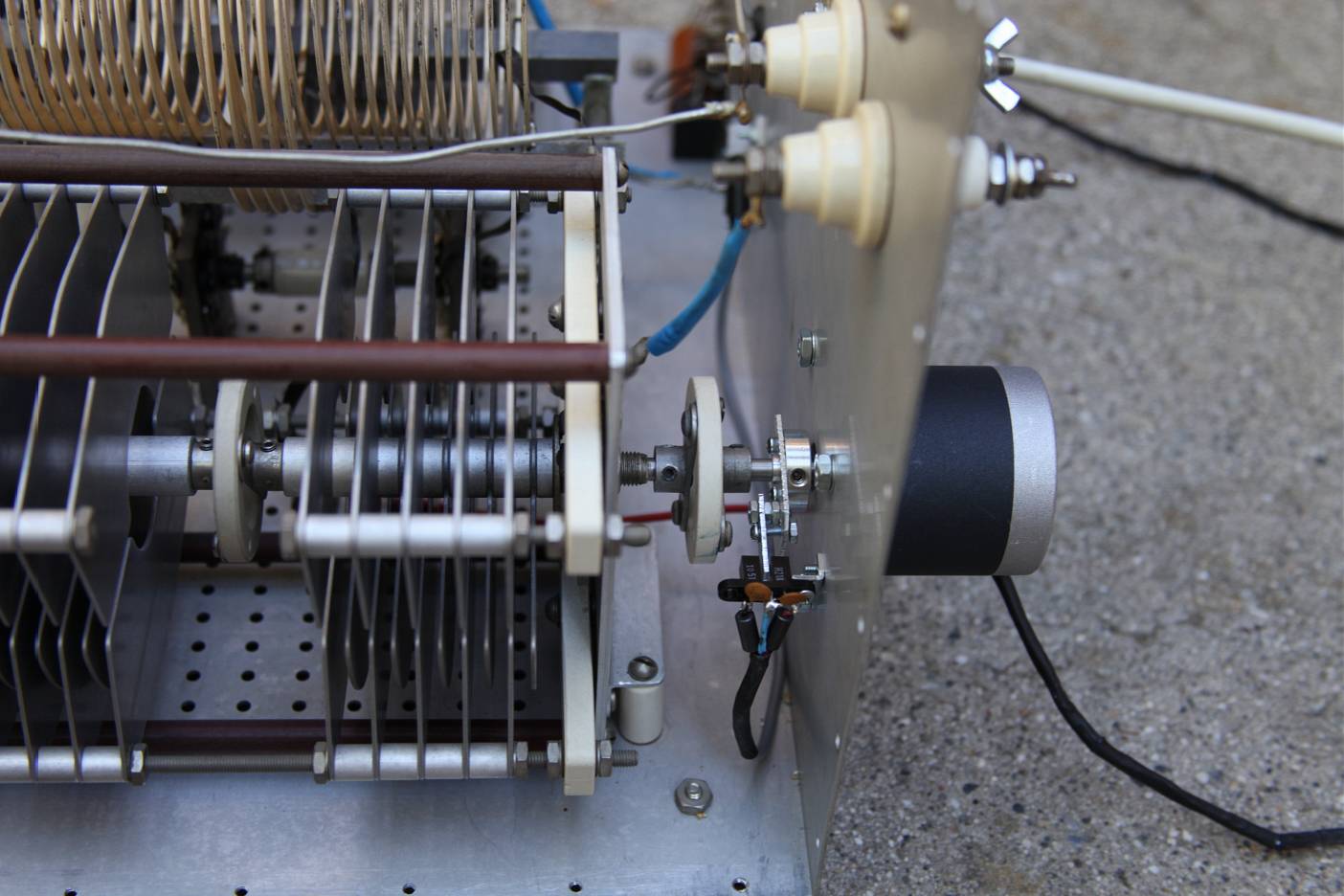

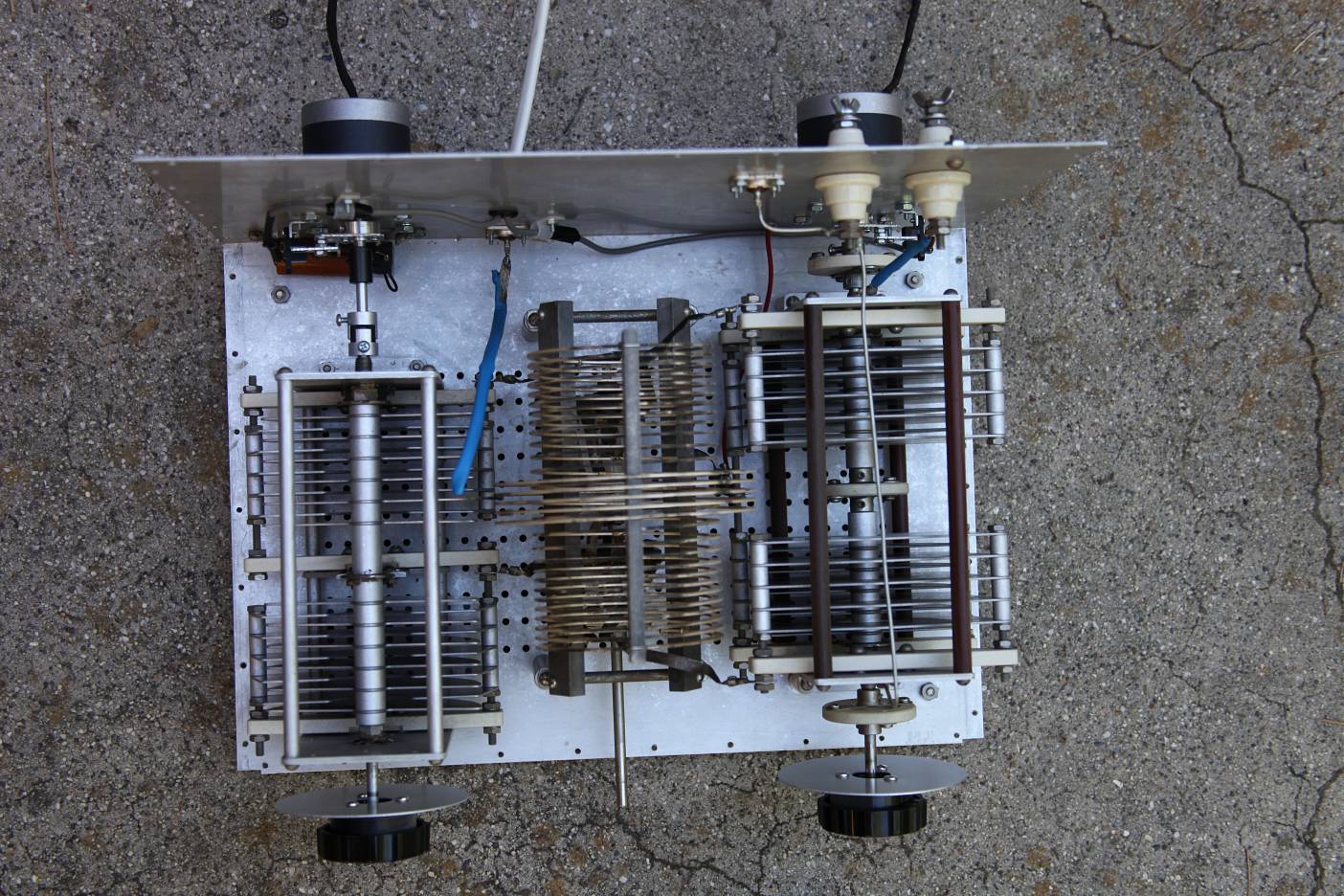

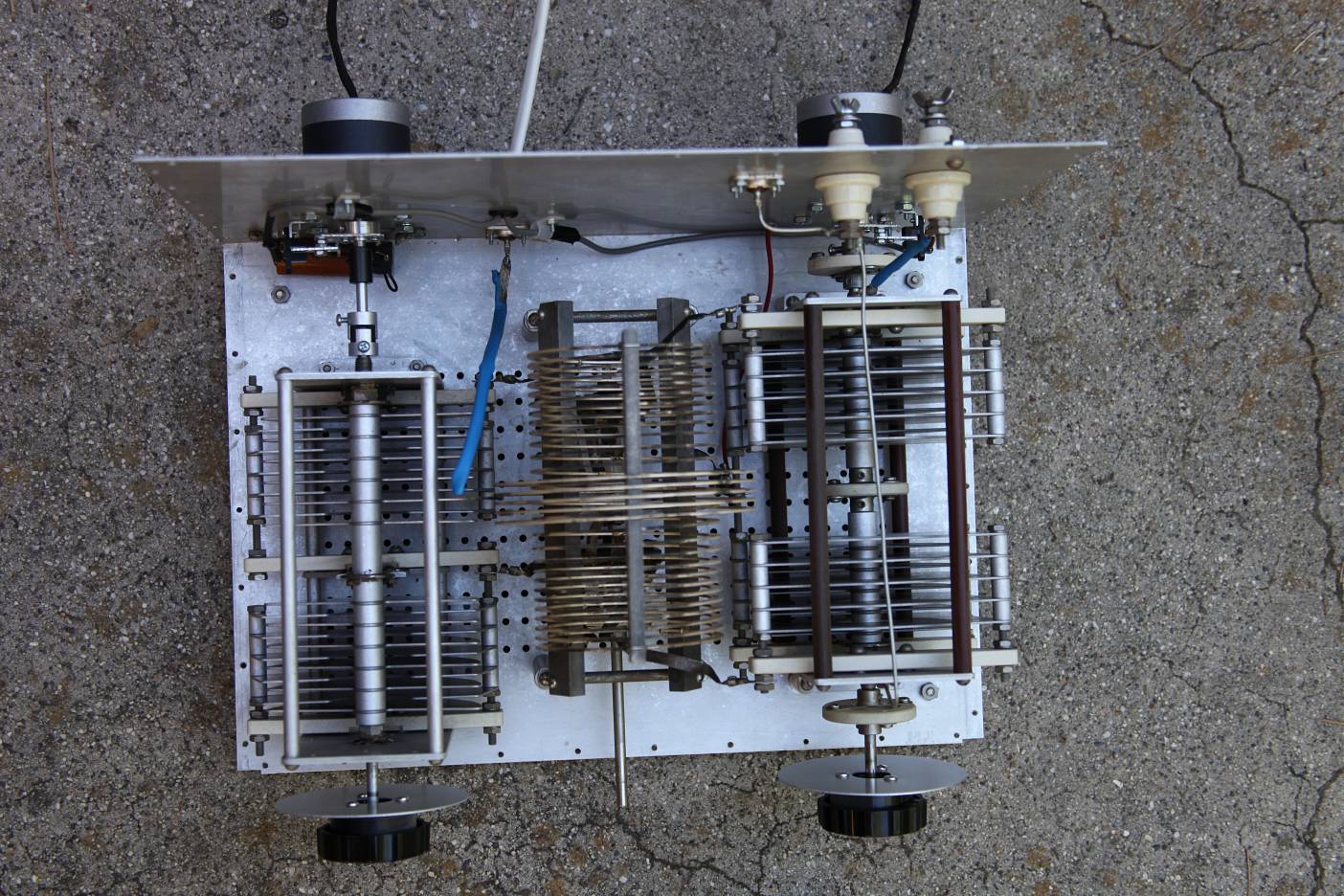

Arduino based Johnson KW Matchbox

Autotuner

I **LOVE** the old Johnson KW Matchbox. It is a great balanced

tuner. It is a great bandpass filter. It will tune

about anything. The problem is that they are fairly high-Q and

requires tuning even with small frequency changes, especially

on 80 meters. 80 meters is a large band in terms of

percentage bandwidth, and the small value of capacitors in the

matchbox yields very high Q.

So... I thought, what about putting stepper motors on one and

controlling with the Icom CI-V interface.

(Hint: for more detail download the images.)

I currently have the Matchbox installed and operating in what I call

pure "Table Mode" where the tuner has table and the stepper motors

tune to a position based on the table. This is done by reading

Icom CI-V frequency messages and going to a look up table to

determine where to set the knobs. It is only a accurate as the

table. So far, weather conditions have been stable, and so has

the tuning. The Arduino uses an Atmel Mega processor with a

built in A/D converter, the though is to tune based upon the

table and then "tweak" for the lowest refelected power, using

the A/D converter to measure SWR. This feature has not yet

been written.

The problem with a table based approach is that if the feeder is

wet, tuning will not be the same as when it is raining,

but I am waiting for rainy season to see how much of a problem that

is.

When the tuner is not tuning, the operator has full control

over the tuner by turning the knobs, so it still operates as a

normal Johnson KW Matchbox.

Watch a video showing how it works

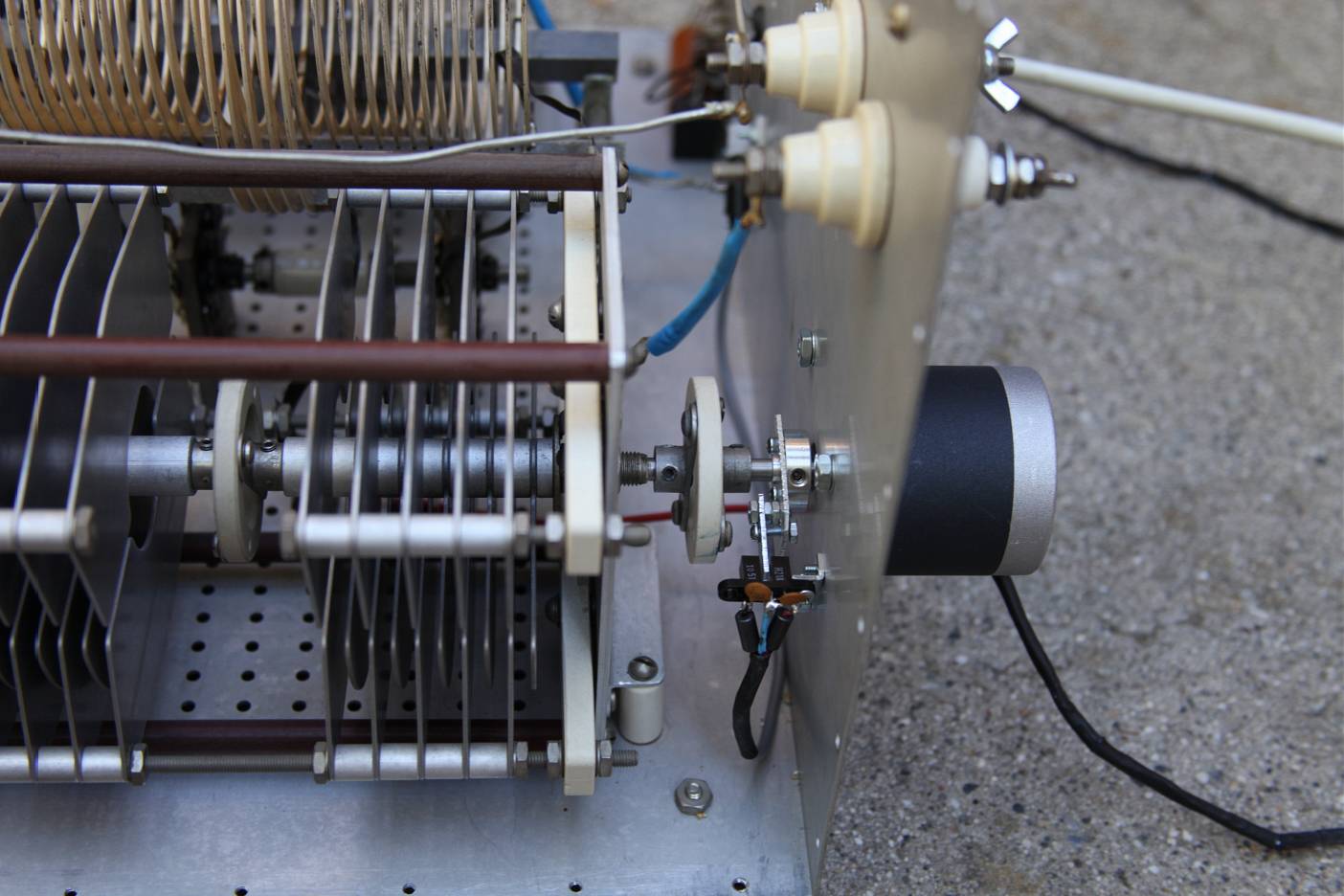

The motor drivers are done through an I2C interface, using an 8 bit

I/O expander, PCF8575N. For each motor, there are two

lines that define the phase, and one line that is an enathe motor

. The other three lines are used to enable power to the LED in

the two opto-couplers and two sense transistors are brought back to

the controller to mark where home is located. The N

channel FETS for the motor drivers must easily be able to handle the

current of the motors. NOR gates should have enough drive

current to operate the power FETs, suggest HC or HCT parts.

Rough schematic

The current code can be downloaded in the following zip file.

This does not include the the LCD library. This software has a

modified version of the CI-V router CI-V software, where all

frequency messages are routed to a global routine, for further

processing.

Current Matchbox Source Software

If you have any questions contact jim at k9jm dot com